Complete Cummins Exhaust System Maintenance Guide

Why Cummins Exhaust Maintenance Matters

- DPF (Diesel Particulate Filter) – Traps soot; requires cleaning or regeneration.

- EGR (Exhaust Gas Recirculation) System – Reduces NOx emissions but can clog.

- Turbocharger & Downpipe – High heat and pressure demand inspection.

- Exhaust Manifold & Piping – Cracks or leaks hurt performance.

Skipping maintenance leads to:

- Reduced MPG (from clogged filters)

- Loss of power (increased backpressure)

- Failed emissions tests (DPF/EGR issues)

- Turbo damage (from excessive heat/stress)

The 50,000Mile Cummins Exhaust Checklist

1. Inspect & Clean the DPF (Diesel Particulate Filter)

Symptoms of a clogged DPF:

- Frequent regeneration cycles

- Loss of power or throttle response

- Check engine light (P2002, P2463 codes)

Solutions:

- Forced regeneration (via scan tool)

- Professional DPF cleaning (ultrasonic or thermal)

- DPF delete pipe (offroad only) – Eliminates future clogs

2. Check the EGR Valve & Cooler

Common EGR problems:

- Carbon buildup restricting airflow

- Cooler leaks causing coolant loss

Maintenance tips:

- Remove and clean the EGR valve (or replace if stuck)

- Flush the EGR cooler if clogged

- Consider an EGR delete kit (offroad only) for longterm reliability

3. Examine the Turbocharger & Exhaust Manifold

Warning signs of trouble:

- Excessive turbo lag

- Oil leaks near the turbo

- Cracked exhaust manifold (loud ticking noise)

What to do:

- Check for shaft play in the turbo

- Retorque manifold bolts (common loosening issue)

- Upgrade to a highflow exhaust manifold if cracked

4. Inspect the Full Exhaust System for Leaks

Common leak points:

- Downpipe gasket (turbo connection)

- Clamps & joints in the piping

- Muffler or resonator welds

Fix leaks ASAP to prevent:

- Soot buildup under the truck

- Loud exhaust drone

- Reduced boost pressure

Bonus: 3 Pro Tips for Cummins Owners

- Use a HighQuality Diesel Additive – Helps keep the DPF cleaner between services.

- Monitor EGTs (Exhaust Gas Temps) – Crucial for towing/heavy loads.

- Upgrade to a HighFlow Exhaust – Less restriction = better performance & longevity.

Keep Your Cummins Running Strong – Shop Maintenance Parts Today!

Featured collection

-

Seguler 1986-1995 Ford F150 F250 F350 Mustang Trucks EGR Simulator Eliminator / Block Off Plate Kit

SEGULEROriginal price $78.58 - Original price $78.58Original price$78.58$78.58 - $78.58Current price $78.58Block Off Plate Material: Aluminum alloy. Easy installation,and convenient to use. Made of CNC milled from aircraft grade Billet aluminum. Will N...

View full detailsOriginal price $78.58 - Original price $78.58Original price$78.58$78.58 - $78.58Current price $78.58 -

Seguler 2009-2019 6.7L Ram Cummins Coolant Bypass Barb Adapter Leak Repair Kit

SEGULEROriginal price $35.99 - Original price $35.99Original price$35.99$35.99 - $35.99Current price $35.99Made of aerospace-grade billet aluminum. Effectively repair the problem of coolant leakage. Resist corrosion and rust for a long time and has good...

View full detailsOriginal price $35.99 - Original price $35.99Original price$35.99$35.99 - $35.99Current price $35.99 -

For 1996-2004 3.8L 4.6L 5.4L Ford GT SVT GT500 V8 Mustang Cobra EGR Delete kit And Exhaust Cap

SEGULEROriginal price $51.99 - Original price $51.99Original price$51.99$51.99 - $51.99Current price $51.99Placement on Vehicle:Front Billet aluminum IAC (idle air control) and EGR (exhaust gas recirculation) block-off plates add a distinctive touch to ...

View full detailsOriginal price $51.99 - Original price $51.99Original price$51.99$51.99 - $51.99Current price $51.99 -

For 2011-2023 6.7L Ford Powerstroke Diesel EGR Delete Kit

SEGULEROriginal price $109.99 - Original price $109.99Original price$109.99$109.99 - $109.99Current price $109.99Material: Aluminum alloy,Stainless steel. 10mm Hole exhaust cover plate for Ford EGT Probes. CNC machine of billet aluminum and stainless steel m...

View full detailsOriginal price $109.99 - Original price $109.99Original price$109.99$109.99 - $109.99Current price $109.99 -

For 2011-2016 6.6L GMC Chevy Duramax Diesel LML EGR Valve Cooler Delete Kit

SEGULEROriginal price $66.49 - Original price $66.49Original price$66.49$66.49 - $66.49Current price $66.49Material: Stainless steel, billet aluminum. Eliminate soot and block of EGR valve prevent high EGT from flow back into engine. Quicker turbo spoo...

View full detailsOriginal price $66.49 - Original price $66.49Original price$66.49$66.49 - $66.49Current price $66.49 -

For 2011-2023 6.7L Ford Powerstroke Diesel EGR Delete Kit

SEGULEROriginal price $85.99 - Original price $85.99Original price$85.99$85.99 - $85.99Current price $85.99Material: Aluminum alloy,Stainless steel. 10mm Hole exhaust cover plate for Ford EGT Probes. CNC machine of billet aluminum and stainless steel m...

View full detailsOriginal price $85.99 - Original price $85.99Original price$85.99$85.99 - $85.99Current price $85.99 -

For 2004-2005 6.6L Chevy GMC Silverado LLY Duramax Diesel EGR Delete Kit

SEGULEROriginal price $92.99 - Original price $92.99Original price$92.99$92.99 - $92.99Current price $92.99Material: Aluminum,Stainless steel,Silicone Eliminates soot build-up and clogged EGR Valves Direct replacement. No installation instruction. No Gl...

View full detailsOriginal price $92.99 - Original price $92.99Original price$92.99$92.99 - $92.99Current price $92.99 -

For 2010-Present Stage 2 ISX 15 CM2250 CM2350 EGR Delete Kit

SEGULEROriginal price $59.99 - Original price $59.99Original price$59.99$59.99 - $59.99Current price $59.99Material: Aluminum Two plates in this kit are made of 6061 aircraft grade billet aluminum anodized and CNC laser cut or CNC machined out of high q...

View full detailsOriginal price $59.99 - Original price $59.99Original price$59.99$59.99 - $59.99Current price $59.99 -

For 2006-2007 6.6L Chevrolet Silverado Classic GMC Duramax LBZ Diesel EGR Valve Cooler Delete Kit

SEGULEROriginal price $63.49 - Original price $63.49Original price$63.49$63.49 - $63.49Current price $63.49Material: Aluminum,Stainless steel,Silicone Eliminates soot build-up and clogged EGR Valves Guaranteed to last under high temperatures and pressu...

View full detailsOriginal price $63.49 - Original price $63.49Original price$63.49$63.49 - $63.49Current price $63.49 -

For 2014-2019 3.0L Dodge Ram 1500 EcoDiesel EGR Valve & Cooler Delete Kit

SEGULEROriginal price $72.99 - Original price $72.99Original price$72.99$72.99 - $72.99Current price $72.99Material: Aluminum,Stainless steel,Silicone. Eliminates soot build-up and clogged EGR Valves. EGR removed and the temperature in the engine compa...

View full detailsOriginal price $72.99 - Original price $72.99Original price$72.99$72.99 - $72.99Current price $72.99 -

Seguler 2003-2007 6.0L FORD Powerstroke Diesel EGR Cooler Delete Kit

SEGULEROriginal price $56.14 - Original price $56.14Original price$56.14$56.14 - $56.14Current price $56.14Material: 304 stainless steel,Aluminum billet. Eliminate ash accumulation and EGR valve blockage. Improve the cooling effect and reduce the engi...

View full detailsOriginal price $56.14 - Original price $56.14Original price$56.14$56.14 - $56.14Current price $56.14 -

Seguler 2010-2024 6.7L Dodge Ram Cummins Diesel EGR Valve Cooler Delete Kit

SEGULEROriginal price $89.99 - Original price $89.99Original price$89.99$89.99 - $89.99Current price $89.99Material: Aluminum alloy,silicone This kit is intended for off road use. Eliminates soot build up and clogged EGR Valves. Hot exhaust gasses ar...

View full detailsOriginal price $89.99 - Original price $89.99Original price$89.99$89.99 - $89.99Current price $89.99 -

Seguler 2003-2007 6.0L Ford F250 F350 Powerstroke Diesel EGR Basic Cooler Kit

SEGULEROriginal price $79.99 - Original price $79.99Original price$79.99$79.99 - $79.99Current price $79.99CNC machine of Aluminum and Stainless Steel billets. Resist corrosion and rust for a long time and has good heat dissipation. Reduce component a...

View full detailsOriginal price $79.99 - Original price $79.99Original price$79.99$79.99 - $79.99Current price $79.99 -

Seguler 2011-2016 6.6L GMC Chevy Duramax Diesel LML Up-Pipe & EGR Valve Cooler Delete Kit

SEGULEROriginal price $173.86 - Original price $173.86Original price$173.86$173.86 - $173.86Current price $173.86Material: 304 Stainless Steel. Reduce the amount of carbon deposited from exhaust to intake. Thanks to its fast airflow and superior engineered ex...

View full detailsOriginal price $173.86 - Original price $173.86Original price$173.86$173.86 - $173.86Current price $173.86 -

For 1983-1997 Ford F150 F250 F350 Mustang Trucks EGR Delete Block Off Plate Kit

SEGULEROriginal price $22.87 - Original price $22.87Original price$22.87$22.87 - $22.87Current price $22.87Material: Aluminum alloy. Easy installation,and convenient to use. Made of CNC milled from aircraft grade Billet aluminum. Will Not Warp or Deform...

View full detailsOriginal price $22.87 - Original price $22.87Original price$22.87$22.87 - $22.87Current price $22.87 -

For 2011-2023 6.7L Ford F250 F350 F450 F550 Powerstroke Diesel EGR Valve Delete Cooler Delete Kit

SEGULEROriginal price $55.99 - Original price $55.99Original price$55.99$55.99 - $55.99Current price $55.99Material: Aluminum alloy,Stainless steel. Black Anodized components for better durability. 12mm Hole exhaust cover plate for Ford EGT Probes. E...

View full detailsOriginal price $55.99 - Original price $55.99Original price$55.99$55.99 - $55.99Current price $55.99 -

For 2017-2023 6.6L Chevy GMC Duramax L5P diesel EGR Valve Cooler Delete kit

SEGULEROriginal price $131.99 - Original price $131.99Original price$131.99$131.99 - $131.99Current price $131.99Material:Aluminum Alloy ,Stainless steel,Silica gel Improved Performance: Eliminating the EGR system leads to better exhaust flow and faster tur...

View full detailsOriginal price $131.99 - Original price $131.99Original price$131.99$131.99 - $131.99Current price $131.99 -

Seguler 2017-2019 L5P Duramax Diesel 4pcs L5P Can Bus Plugs Connector Replacement

SEGULEROriginal price $59.99 - Original price $59.99Original price$59.99$59.99 - $59.99Current price $59.99Material: ABS For use with an Aftermarket Exhaust System. A new engine calibration is required. Plugs will replace NOX and DEF modules. The L...

View full detailsOriginal price $59.99 - Original price $59.99Original price$59.99$59.99 - $59.99Current price $59.99 -

For 2007-2010 Cummins ISX CM871 EGR Plug Kit Stage 2 Plates and Plugs Aluminum

SEGULEROriginal price $67.99 - Original price $67.99Original price$67.99$67.99 - $67.99Current price $67.99Material:304 Stainless Steel & Billet Aluminum. High-temperature graphite gaskets are adopted to prevent leakage. Used to delete the EGR val...

View full detailsOriginal price $67.99 - Original price $67.99Original price$67.99$67.99 - $67.99Current price $67.99 -

For 11-23 Ford 6.7L Powerstroke CCV/PCV Reroute/Delete Engine Ventilation Kit

SEGULEROriginal price $72.00 - Original price $72.00Original price$72.00$72.00 - $72.00Current price $72.00Material:Aluminum alloy rubber. Black Anodized components for better durability. This Crankcase Ventilation System provides a SOLID solution to ...

View full detailsOriginal price $72.00 - Original price $72.00Original price$72.00$72.00 - $72.00Current price $72.00 -

Seguler 2020-2023 chevy duramax L5P Diesel Can Bus Plugs Connector

SEGULEROriginal price $69.99 - Original price $69.99Original price$69.99$69.99 - $69.99Current price $69.99For use with aftermarket exhaust systems or delete pipes Used when removing the DPF/DEF systems These plugs will go in place of the NOx and DEF mo...

View full detailsOriginal price $69.99 - Original price $69.99Original price$69.99$69.99 - $69.99Current price $69.99 -

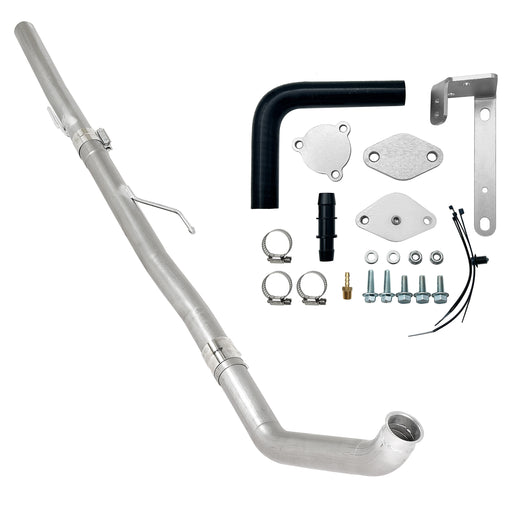

Seguler 3" Ecodiesel DPF Delete Pipe & EGR Delete kit for 2014-2018 3.0L Ram

SEGULEROriginal price $342.00 - Original price $342.00Original price$342.00$342.00 - $342.00Current price $342.00Material: High quality stainless steel Inlet Diameter: 3.0" Eliminates soot build-up and clogged EGR Valves Specialized designs to ensure a perfec...

View full detailsOriginal price $342.00 - Original price $342.00Original price$342.00$342.00 - $342.00Current price $342.00 -

For 2013-2018 6.7L Dodge RAM 2500 3500 Cummins Diesel EGR Delete Cooler Throttle Valve Delete Kit

SEGULEROriginal price $112.00 - Original price $112.00Original price$112.00$112.00 - $112.00Current price $112.00Material: Aluminum alloy,silicone Aluminum material can resist corrosion and rust for a long time and has good heat dissipation. EGR delete stan...

View full detailsOriginal price $112.00 - Original price $112.00Original price$112.00$112.00 - $112.00Current price $112.00 -

For 2013-2023 6.7L Dodge Ram Cummins Cab & Chassis EGR Delete Kit Diesel

SEGULEROriginal price $62.99 - Original price $62.99Original price$62.99$62.99 - $62.99Current price $62.99Material: Aluminum alloy. Eliminates soot build up and clogged EGR Valves. Hot exhaust gasses are not being re-routed back into the motor. Coo...

View full detailsOriginal price $62.99 - Original price $62.99Original price$62.99$62.99 - $62.99Current price $62.99 -

For 2007-2010 6.6L Chevy GMC LMM Duramax EGR Valve Cooler Delete Kit Fit

SEGULEROriginal price $61.99 - Original price $61.99Original price$61.99$61.99 - $61.99Current price $61.99Material: Aluminum alloy,Stainless steel. Improves engine life by eliminating soot build-up and reducing fuel consumption. EGR valve cooler delet...

View full detailsOriginal price $61.99 - Original price $61.99Original price$61.99$61.99 - $61.99Current price $61.99

Leave a comment