Diesel Truck Blowing White Smoke? Causes and Remediation

1.Fundamental Mechanisms of White Smoke Formation

White smoke in diesel engines results from the presence of unburned fuel or coolant in the exhaust stream. Unlike gasoline engines where white smoke typically indicates coolant intrusion, diesel engines present more complex diagnostic challenges due to:

Lower exhaust temperatures (200300°F at idle vs. 600900°F under load)

Heterogeneous combustion characteristics

Aftertreatment system interactions (in post2007 engines)

The smoke appears white due to:

- Microdroplet formation (1050μm diameter)

- Light refraction through hydrocarbon/water vapor

- Temperaturedependent particle agglomeration

2. Comprehensive Diagnostic Framework

2.1 Initial Assessment Protocol

Step 1: Smoke Characterization

Coldstart only vs. continuous emission

Temperature dependence pattern

Odor analysis (sweet = coolant, acrid = fuel, ammonialike = DEF)

Step 2: Engine Parameter Monitoring

Coolant temperature vs. smoke correlation

Fuel rail pressure stability

Exhaust backpressure readings

Cylinder contribution balance (via scan tool)

Step 3: Fluid Analysis

Coolant hydrocarbon test

Oil viscosity and flash point verification

Fuel water content measurement

3. Root Cause Analysis

3.1 Fuel System Pathologies

Injection Timing Deviations:

>3° retarded timing increases smoke opacity by 4060%

Common causes:

Stretched timing chain (ISB 5.9L)

CP3 pump wear (ISB 6.7L)

Faulty cam/crank position sensors

Injector Performance Issues:

Nozzle coking increases droplet size from 15μm to >50μm

Seat leakage rates >5cc/min cause continuous smoke

Stiction problems manifest as 24% imbalance rates

Diagnostic Protocol:

Injector cutout test with smoke observation

Return flow measurement (spec: <100ml/min at idle)

Current waveform analysis

3.2 Combustion Chamber Intrusion

Cylinder Head Failure Modes:

Microcracks in prechamber (common in 24V 5.9L)

Valve seat distortion (high EGT engines)

Fire deck erosion (coolant passage corrosion)

Head Gasket Failure Patterns:

Type 1: Coolanttocylinder (white smoke + pressure)

Type 2: Coolanttooil (emulsification)

Type 3: Coolanttoexhaust (steam emission)

Verification Methods:

Combustion leak dye test

Cylinder leakage >25% indicates sealing failure

Coolant system pressure decay test

3.3 Aftertreatment System Interactions

DPF/SCRRelated Smoke:

DEF crystallization creates NH₄HSO₄ deposits

Low SCR temperatures (<400°F) prevent urea decomposition

Passive regeneration failures increase HC slip

Diagnostic Indicators:

Delta P across DPF >15" H₂O

DEF dosing rates >150% of normal

NOx sensor drift >20%

4. Advanced Repair Methodologies

4.1 Fuel System Rectification

Injector Service Procedures:

1. Nozzle pop testing (180200 bar opening pressure)

2. Seat leakage verification (<2cc/min)

3. Spray pattern analysis (15° cone angle)

Timing System Rebuild:

Chain stretch limit: >3% of original length

Gear backlash: 0.100.15mm

Phaser solenoid resistance: 1015Ω

4.2 Cylinder Head Rehabilitation

Machining Specifications:

Surface flatness: <0.003"/12"

Fire deck thickness: ≥minimum spec +0.010"

Valve seat concentricity: <0.002" TIR

Assembly Torque Sequence:

M14 head bolts: 90ftlb + 90° + 90°

M16 studs: 110ftlb + 120°

4.3 Aftertreatment Restoration

DPF Cleaning Protocol:

1. Thermal regeneration (1200°F for 45min)

2. Pneumatic soot removal (60psi reverse flow)

3. Chemical bath (pHneutral cleaner)

SCR System Service:

DEF injector flow test: 8001200ml/min @ 60psi

Mixer integrity inspection

Catalyst substrate verification

5. Preventative Maintenance Strategies

Fuel System Preservation:

Biocide treatment every 10k miles

2μm final filtration (recommended)

Lubricity additive (HFRR <460μm)

Cooling System Management:

Nitritefree coolant (for 6.7L engines)

Pressure cap verification (1316psi)

Annual coolant analysis

Aftertreatment Maintenance:

Forced regeneration every 50k miles

DEF quality testing (32.5% urea)

DPF ash loading monitoring

6. Diagnostic Decision Tree

7. Technical Reference Data

Cummins 5.9L/6.7L Critical Specifications:

| Parameter | 5.9L ISB | 6.7L ISB |

| Compression Ratio | 17.3:1 | 16.2:1 |

| Injector Opening Pressure | 310 bar | 250 bar |

| Max EGT (Continuous) | 1250°F | 1350°F |

| DPF Regeneration Temp | N/A | 1112°F |

Smoke Opacity Standards:

EPA Tier 3: <20% opacity

CARB: <5% for >90% of test cycle

SAE J1667: <50% snap acceleration

This technical bulletin provides comprehensive diagnostic methodology for service professionals. Always refer to manufacturer service manuals for vehiclespecific procedures and specifications.

Featured collection

-

Seguler 1986-1995 Ford F150 F250 F350 Mustang Trucks EGR Simulator Eliminator / Block Off Plate Kit

SEGULEROriginal price $78.58 - Original price $78.58Original price$78.58$78.58 - $78.58Current price $78.58Block Off Plate Material: Aluminum alloy. Easy installation,and convenient to use. Made of CNC milled from aircraft grade Billet aluminum. Will N...

View full detailsOriginal price $78.58 - Original price $78.58Original price$78.58$78.58 - $78.58Current price $78.58 -

Seguler 2009-2019 6.7L Ram Cummins Coolant Bypass Barb Adapter Leak Repair Kit

SEGULEROriginal price $35.99 - Original price $35.99Original price$35.99$35.99 - $35.99Current price $35.99Made of aerospace-grade billet aluminum. Effectively repair the problem of coolant leakage. Resist corrosion and rust for a long time and has good...

View full detailsOriginal price $35.99 - Original price $35.99Original price$35.99$35.99 - $35.99Current price $35.99 -

For 1996-2004 3.8L 4.6L 5.4L Ford GT SVT GT500 V8 Mustang Cobra EGR Delete kit And Exhaust Cap

SEGULEROriginal price $51.99 - Original price $51.99Original price$51.99$51.99 - $51.99Current price $51.99Placement on Vehicle:Front Billet aluminum IAC (idle air control) and EGR (exhaust gas recirculation) block-off plates add a distinctive touch to ...

View full detailsOriginal price $51.99 - Original price $51.99Original price$51.99$51.99 - $51.99Current price $51.99 -

For 2011-2023 6.7L Ford Powerstroke Diesel EGR Delete Kit

SEGULEROriginal price $109.99 - Original price $109.99Original price$109.99$109.99 - $109.99Current price $109.99Material: Aluminum alloy,Stainless steel. 10mm Hole exhaust cover plate for Ford EGT Probes. CNC machine of billet aluminum and stainless steel m...

View full detailsOriginal price $109.99 - Original price $109.99Original price$109.99$109.99 - $109.99Current price $109.99 -

For 2011-2016 6.6L GMC Chevy Duramax Diesel LML EGR Valve Cooler Delete Kit

SEGULEROriginal price $66.49 - Original price $66.49Original price$66.49$66.49 - $66.49Current price $66.49Material: Stainless steel, billet aluminum. Eliminate soot and block of EGR valve prevent high EGT from flow back into engine. Quicker turbo spoo...

View full detailsOriginal price $66.49 - Original price $66.49Original price$66.49$66.49 - $66.49Current price $66.49 -

For 2004-2005 6.6L Chevy GMC Silverado LLY Duramax Diesel EGR Delete Kit

SEGULEROriginal price $92.99 - Original price $92.99Original price$92.99$92.99 - $92.99Current price $92.99Material: Aluminum,Stainless steel,Silicone Eliminates soot build-up and clogged EGR Valves Direct replacement. No installation instruction. No Gl...

View full detailsOriginal price $92.99 - Original price $92.99Original price$92.99$92.99 - $92.99Current price $92.99 -

For 2010-Present Stage 2 ISX 15 CM2250 CM2350 EGR Delete Kit

SEGULEROriginal price $59.99 - Original price $59.99Original price$59.99$59.99 - $59.99Current price $59.99Material: Aluminum Two plates in this kit are made of 6061 aircraft grade billet aluminum anodized and CNC laser cut or CNC machined out of high q...

View full detailsOriginal price $59.99 - Original price $59.99Original price$59.99$59.99 - $59.99Current price $59.99 -

For 2011-2023 6.7L Ford Powerstroke Diesel EGR Delete Kit

SEGULEROriginal price $85.99 - Original price $85.99Original price$85.99$85.99 - $85.99Current price $85.99Material: Aluminum alloy,Stainless steel. 10mm Hole exhaust cover plate for Ford EGT Probes. CNC machine of billet aluminum and stainless steel m...

View full detailsOriginal price $85.99 - Original price $85.99Original price$85.99$85.99 - $85.99Current price $85.99 -

For 2006-2007 6.6L Chevrolet Silverado Classic GMC Duramax LBZ Diesel EGR Valve Cooler Delete Kit

SEGULEROriginal price $63.49 - Original price $63.49Original price$63.49$63.49 - $63.49Current price $63.49Material: Aluminum,Stainless steel,Silicone Eliminates soot build-up and clogged EGR Valves Guaranteed to last under high temperatures and pressu...

View full detailsOriginal price $63.49 - Original price $63.49Original price$63.49$63.49 - $63.49Current price $63.49 -

For 2014-2019 3.0L Dodge Ram 1500 EcoDiesel EGR Valve & Cooler Delete Kit

SEGULEROriginal price $72.99 - Original price $72.99Original price$72.99$72.99 - $72.99Current price $72.99Material: Aluminum,Stainless steel,Silicone. Eliminates soot build-up and clogged EGR Valves. EGR removed and the temperature in the engine compa...

View full detailsOriginal price $72.99 - Original price $72.99Original price$72.99$72.99 - $72.99Current price $72.99 -

Seguler 2003-2007 6.0L FORD Powerstroke Diesel EGR Cooler Delete Kit

SEGULEROriginal price $56.14 - Original price $56.14Original price$56.14$56.14 - $56.14Current price $56.14Material: 304 stainless steel,Aluminum billet. Eliminate ash accumulation and EGR valve blockage. Improve the cooling effect and reduce the engi...

View full detailsOriginal price $56.14 - Original price $56.14Original price$56.14$56.14 - $56.14Current price $56.14 -

Seguler 2010-2024 6.7L Dodge Ram Cummins Diesel EGR Valve Cooler Delete Kit

SEGULEROriginal price $89.99 - Original price $89.99Original price$89.99$89.99 - $89.99Current price $89.99Material: Aluminum alloy,silicone This kit is intended for off road use. Eliminates soot build up and clogged EGR Valves. Hot exhaust gasses ar...

View full detailsOriginal price $89.99 - Original price $89.99Original price$89.99$89.99 - $89.99Current price $89.99 -

Seguler 2003-2007 6.0L Ford F250 F350 Powerstroke Diesel EGR Basic Cooler Kit

SEGULEROriginal price $79.99 - Original price $79.99Original price$79.99$79.99 - $79.99Current price $79.99CNC machine of Aluminum and Stainless Steel billets. Resist corrosion and rust for a long time and has good heat dissipation. Reduce component a...

View full detailsOriginal price $79.99 - Original price $79.99Original price$79.99$79.99 - $79.99Current price $79.99 -

Seguler 2011-2016 6.6L GMC Chevy Duramax Diesel LML Up-Pipe & EGR Valve Cooler Delete Kit

SEGULEROriginal price $173.86 - Original price $173.86Original price$173.86$173.86 - $173.86Current price $173.86Material: 304 Stainless Steel. Reduce the amount of carbon deposited from exhaust to intake. Thanks to its fast airflow and superior engineered ex...

View full detailsOriginal price $173.86 - Original price $173.86Original price$173.86$173.86 - $173.86Current price $173.86 -

For 1983-1997 Ford F150 F250 F350 Mustang Trucks EGR Delete Block Off Plate Kit

SEGULEROriginal price $22.87 - Original price $22.87Original price$22.87$22.87 - $22.87Current price $22.87Material: Aluminum alloy. Easy installation,and convenient to use. Made of CNC milled from aircraft grade Billet aluminum. Will Not Warp or Deform...

View full detailsOriginal price $22.87 - Original price $22.87Original price$22.87$22.87 - $22.87Current price $22.87 -

For 2011-2023 6.7L Ford F250 F350 F450 F550 Powerstroke Diesel EGR Valve Delete Cooler Delete Kit

SEGULEROriginal price $55.99 - Original price $55.99Original price$55.99$55.99 - $55.99Current price $55.99Material: Aluminum alloy,Stainless steel. Black Anodized components for better durability. 12mm Hole exhaust cover plate for Ford EGT Probes. E...

View full detailsOriginal price $55.99 - Original price $55.99Original price$55.99$55.99 - $55.99Current price $55.99 -

For 2017-2023 6.6L Chevy GMC Duramax L5P diesel EGR Valve Cooler Delete kit

SEGULEROriginal price $131.99 - Original price $131.99Original price$131.99$131.99 - $131.99Current price $131.99Material:Aluminum Alloy ,Stainless steel,Silica gel Improved Performance: Eliminating the EGR system leads to better exhaust flow and faster tur...

View full detailsOriginal price $131.99 - Original price $131.99Original price$131.99$131.99 - $131.99Current price $131.99 -

For 2007-2010 Cummins ISX CM871 EGR Plug Kit Stage 2 Plates and Plugs Aluminum

SEGULEROriginal price $67.99 - Original price $67.99Original price$67.99$67.99 - $67.99Current price $67.99Material:304 Stainless Steel & Billet Aluminum. High-temperature graphite gaskets are adopted to prevent leakage. Used to delete the EGR val...

View full detailsOriginal price $67.99 - Original price $67.99Original price$67.99$67.99 - $67.99Current price $67.99 -

Seguler 2017-2019 L5P Duramax Diesel 4pcs L5P Can Bus Plugs Connector Replacement

SEGULEROriginal price $59.99 - Original price $59.99Original price$59.99$59.99 - $59.99Current price $59.99Material: ABS For use with an Aftermarket Exhaust System. A new engine calibration is required. Plugs will replace NOX and DEF modules. The L...

View full detailsOriginal price $59.99 - Original price $59.99Original price$59.99$59.99 - $59.99Current price $59.99 -

For 11-23 Ford 6.7L Powerstroke CCV/PCV Reroute/Delete Engine Ventilation Kit

SEGULEROriginal price $72.00 - Original price $72.00Original price$72.00$72.00 - $72.00Current price $72.00Material:Aluminum alloy rubber. Black Anodized components for better durability. This Crankcase Ventilation System provides a SOLID solution to ...

View full detailsOriginal price $72.00 - Original price $72.00Original price$72.00$72.00 - $72.00Current price $72.00 -

Seguler 2020-2023 chevy duramax L5P Diesel Can Bus Plugs Connector

SEGULEROriginal price $69.99 - Original price $69.99Original price$69.99$69.99 - $69.99Current price $69.99For use with aftermarket exhaust systems or delete pipes Used when removing the DPF/DEF systems These plugs will go in place of the NOx and DEF mo...

View full detailsOriginal price $69.99 - Original price $69.99Original price$69.99$69.99 - $69.99Current price $69.99 -

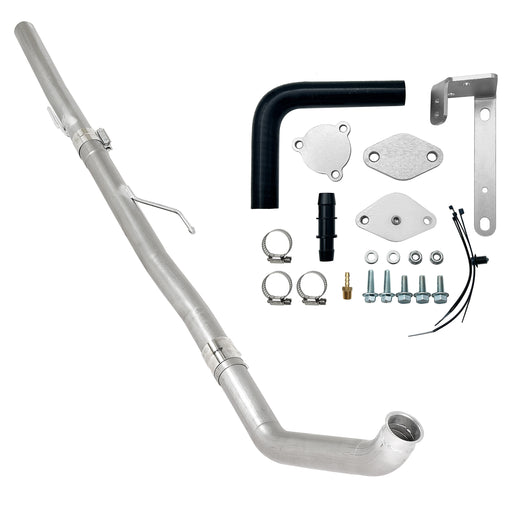

Seguler 3" Ecodiesel DPF Delete Pipe & EGR Delete kit for 2014-2018 3.0L Ram

SEGULEROriginal price $342.00 - Original price $342.00Original price$342.00$342.00 - $342.00Current price $342.00Material: High quality stainless steel Inlet Diameter: 3.0" Eliminates soot build-up and clogged EGR Valves Specialized designs to ensure a perfec...

View full detailsOriginal price $342.00 - Original price $342.00Original price$342.00$342.00 - $342.00Current price $342.00 -

For 2013-2018 6.7L Dodge RAM 2500 3500 Cummins Diesel EGR Delete Cooler Throttle Valve Delete Kit

SEGULEROriginal price $112.00 - Original price $112.00Original price$112.00$112.00 - $112.00Current price $112.00Material: Aluminum alloy,silicone Aluminum material can resist corrosion and rust for a long time and has good heat dissipation. EGR delete stan...

View full detailsOriginal price $112.00 - Original price $112.00Original price$112.00$112.00 - $112.00Current price $112.00 -

For 2013-2023 6.7L Dodge Ram Cummins Cab & Chassis EGR Delete Kit Diesel

SEGULEROriginal price $62.99 - Original price $62.99Original price$62.99$62.99 - $62.99Current price $62.99Material: Aluminum alloy. Eliminates soot build up and clogged EGR Valves. Hot exhaust gasses are not being re-routed back into the motor. Coo...

View full detailsOriginal price $62.99 - Original price $62.99Original price$62.99$62.99 - $62.99Current price $62.99 -

For 2007-2010 6.6L Chevy GMC LMM Duramax EGR Valve Cooler Delete Kit Fit

SEGULEROriginal price $61.99 - Original price $61.99Original price$61.99$61.99 - $61.99Current price $61.99Material: Aluminum alloy,Stainless steel. Improves engine life by eliminating soot build-up and reducing fuel consumption. EGR valve cooler delet...

View full detailsOriginal price $61.99 - Original price $61.99Original price$61.99$61.99 - $61.99Current price $61.99

Leave a comment