What is an Intake Manifold? Your Engine's Breathing System Explained

If you've ever wondered how your diesel engine breathes, the intake manifold is where the magic begins. This often-overlooked component serves as the critical gateway between your air intake system and your engine's combustion chambers. But what does an intake manifold do exactly, and why does it matter for performance? Whether you're troubleshooting engine issues or considering upgrades, understanding this component is essential for any diesel owner.

In this comprehensive guide, we'll explore exactly what an intake manifold does, explain where is the intake manifold located in your engine bay, and show how upgrading this component can transform your truck's performance. From basic function to advanced performance modifications, you'll learn why this "air highway" deserves your attention.

Understanding the Basics: What is an Intake Manifold?

The Fundamental Definition

An intake manifold is a series of pipes or passages that distribute air (or air-fuel mixture in gasoline engines) from the throttle body or intake piping to each cylinder's intake ports. Think of it as the sophisticated air distribution network that ensures each cylinder receives exactly what it needs for optimal combustion.

The Evolution of Intake Manifolds

From simple cast iron designs to today's complex plastic and aluminum assemblies, intake manifolds have evolved significantly:

- Early designs: Simple cast iron or aluminum runners

- Modern gasoline engines: Often plastic with integrated components

- Diesel applications: Typically aluminum with integrated EGR passages

- Performance designs: Optimized for airflow and efficiency

What Does an Intake Manifold Do? The Critical Functions

Primary Function: Air Distribution

The most obvious answer to "what does an intake manifold do?" is air distribution. But it's not just about moving air—it's about doing it efficiently and evenly:

Equal Distribution

- Ensures each cylinder receives equal airflow

- Maintains consistent air-fuel ratios across all cylinders

- Prevents "lean" or "rich" conditions in individual cylinders

- Supports balanced engine operation

Velocity Maintenance

- Tapered runner designs maintain air velocity

- Proper velocity improves cylinder filling efficiency

- Enhances low-end torque characteristics

- Optimizes combustion efficiency

Secondary Functions and Integration

Modern intake manifolds do much more than just distribute air:

EGR System Integration

- Many diesel manifolds include EGR passages

- Routes exhaust gases back into intake stream

- Creates complexity and potential failure points

- Can lead to carbon buildup and restriction

Sensor Mounting Points

- Provides mounting for MAP (Manifold Absolute Pressure) sensors

- May include temperature sensor ports

- Supports various emissions control sensors

- Integral to modern engine management

Mounting Surface for Components

- Often supports throttle bodies

- May include mounting for fuel rails (gasoline)

- Provides attachment points for various brackets

- Serves as structural component in some designs

Where is the Intake Manifold Located?

Typical Placement in Diesel Engines

When asking "where is the intake manifold?" in your diesel truck:

Common Locations

- Top of the engine: Between cylinder heads on V-configuration engines

- Side-mounted: On inline engines like the Cummins 6.7L

- Under intake piping: Often hidden beneath other components

- Integrated with other systems: Connected to EGR coolers, intercooler piping, etc.

Visual Identification

- Typically aluminum (sometimes plastic in newer designs)

- Multiple runners leading to cylinder head ports

- Various sensors and connections attached

- Connected to air intake system at one end

Access and Service Considerations

Knowing where is the intake manifold helps with maintenance:

- Often requires removal of other components for access

- Coolant lines may need disconnection (if EGR cooler integrated)

- Electrical connectors for sensors must be carefully disconnected

- Proper torque sequences are critical during reinstallation

Common Intake Manifold Problems in Diesel Engines

Carbon Buildup Issues

One of the most common problems in modern diesel manifolds:

EGR-Related Contamination

- Soot from exhaust gases accumulates in passages

- Creates restriction and reduces airflow

- Can break off and damage turbochargers or intercoolers

- Requires periodic cleaning in severe cases

Performance Impacts

- Reduced horsepower and torque

- Poor fuel economy

- Uneven cylinder operation

- Increased exhaust temperatures

Leaks and Failure Points

Gasket Failures

- Intake manifold gaskets can deteriorate over time

- Creates vacuum leaks affecting engine operation

- May allow coolant into intake (in some designs)

- Requires complete removal for replacement

Cracking and Physical Damage

- Thermal cycling can cause cracks in older manifolds

- Improper installation or over-torquing can cause damage

- Impact damage from other repairs

- Corrosion in certain environments

Restriction and Flow Limitations

Factory designs often prioritize cost over optimal flow:

- Sharp bends and transitions create turbulence

- Small runner diameters restrict high-RPM airflow

- Poor plenum design creates uneven distribution

- Integrated EGR systems create unnecessary complexity

Featured Performance Solution: Cummins High-Flow Intake Manifold Elbow

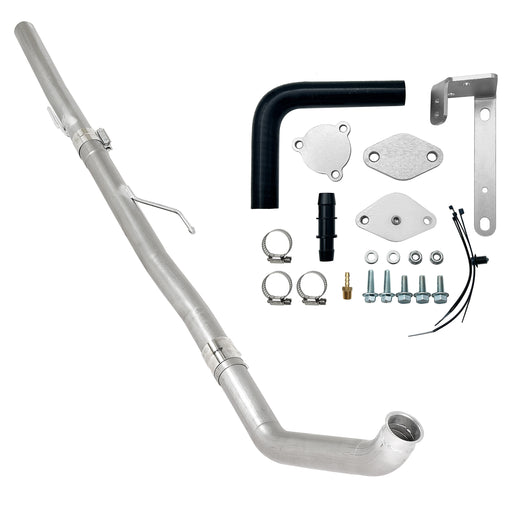

2007-2018 6.7L Dodge RAM Cummins 3.5inch High Flow Intake Manifold Elbow Tube

Addressing Factory Limitations

The factory intake elbow on 2007-2018 6.7L Cummins engines represents a significant airflow restriction. Our high-flow replacement solves this problem with intelligent engineering:

Design Features:

- 3.5-inch diameter (vs. restrictive factory design)

- Mandrel-bent construction for smooth, consistent airflow

- Aircraft-grade aluminum for durability and heat dissipation

- Precision CNC machining ensures perfect fitment

- Complete bolt-on design requires no modification

Performance Benefits:

- Reduces intake restriction for better turbo response

- Lowers intake air temperatures for improved combustion

- Eliminates factory failure points and potential leaks

- Improves overall engine efficiency and power delivery

- Direct fitment for 2007-2018 6.7L Cummins applications

Installation Considerations and Professional Advice

DIY vs. Professional Installation

While some enthusiasts install intake components themselves:

Professional Installation Benefits

- Ensures perfect alignment and sealing

- Proper torque sequencing for gasket longevity

- Professional inspection of related components

- Warranty protection on labor and installation

DIY Considerations

- Mechanical experience required

- Proper torque wrench essential

- Careful handling of sensors and connections

- Coolant system knowledge (if EGR system involved)

Complementary Upgrades

This intake elbow works exceptionally well with:

Supporting Modifications

- Performance air intake systems

- Upgraded intercooler piping

- Enhanced turbo components

- Custom tuning to optimize airflow changes

Maintenance and Care for Your Intake System

Regular Maintenance Practices

Keep your intake system performing optimally:

Visual Inspections

- Check for leaks at connections and gaskets

- Inspect for carbon buildup in accessible areas

- Look for cracks or damage in components

- Ensure all clamps and connections are secure

Cleaning Procedures

- Regular cleaning of air filter and intake piping

- Professional cleaning for severe carbon buildup

- Careful cleaning of sensors and connections

- Use appropriate cleaners for your specific materials

Troubleshooting Common Issues

Vacuum Leak Diagnosis

- Unusual whistling or hissing sounds

- Rough idle or stalling

- Poor fuel economy

- Check engine lights for lean conditions

Performance Issues

- Reduced power output

- Poor throttle response

- Increased turbo lag

- Higher exhaust temperatures

Conclusion:

Understanding what an intake manifold does reveals just how critical this component is to your engine's performance and efficiency. From basic air distribution to complex emissions control integration, this component works tirelessly to ensure your diesel breathes properly.

Ready to improve your diesel's breathing? Visit www.seguler.com to explore this intake upgrade and our complete range of diesel performance solutions. Our technical experts can help you select the right components to optimize your truck's intake, exhaust, and overall performance.

FAQs About Intake Manifolds

Q1: What does an intake manifold do for engine performance?

A1: The intake manifold distributes air evenly to all cylinders, maintains proper air velocity for efficient cylinder filling, and in modern engines, integrates various sensors and emissions systems critical for optimal performance.

Q2: Where is the intake manifold typically located?

A2: On most diesel engines, the intake manifold is located on top of the engine between cylinder heads (V-configuration) or along the side (inline engines), connected to the air intake system and leading to each cylinder's intake ports.

Q3: Can a bad intake manifold affect fuel economy?

A3: Yes, a leaking or restricted intake manifold can significantly impact fuel economy by creating incorrect air-fuel ratios, causing the engine computer to compensate with more fuel, and reducing overall combustion efficiency.

Q4: How do I know if my intake manifold needs replacement?

A4: Signs include vacuum leaks (hissing sounds, rough idle), visible cracks or damage, coolant in intake (in some designs), carbon buildup restricting flow, or when upgrading for performance reasons.

Q5: What are the benefits of upgrading to a high-flow intake manifold?

A5: Benefits include reduced restriction for better airflow, improved throttle response, increased horsepower potential, lower intake temperatures, elimination of factory failure points, and enhanced engine efficiency.

Featured collection

-

Seguler 1986-1995 Ford F150 F250 F350 Mustang Trucks EGR Simulator Eliminator / Block Off Plate Kit

SEGULEROriginal price $79.99 - Original price $79.99Original price$79.99$79.99 - $79.99Current price $79.99Block Off Plate Material: Aluminum alloy. Easy installation,and convenient to use. Made of CNC milled from aircraft grade Billet aluminum. Will N...

View full detailsOriginal price $79.99 - Original price $79.99Original price$79.99$79.99 - $79.99Current price $79.99 -

Seguler 2009-2019 6.7L Ram Cummins Coolant Bypass Barb Adapter Leak Repair Kit

SEGULEROriginal price $35.99 - Original price $35.99Original price$35.99$35.99 - $35.99Current price $35.99Made of aerospace-grade billet aluminum. Effectively repair the problem of coolant leakage. Resist corrosion and rust for a long time and has good...

View full detailsOriginal price $35.99 - Original price $35.99Original price$35.99$35.99 - $35.99Current price $35.99 -

For 2011-2023 6.7L Ford Powerstroke Diesel EGR Delete Kit

SEGULEROriginal price $109.99 - Original price $109.99Original price$109.99$109.99 - $109.99Current price $109.99Material: Aluminum alloy,Stainless steel. 10mm Hole exhaust cover plate for Ford EGT Probes. CNC machine of billet aluminum and stainless steel m...

View full detailsOriginal price $109.99 - Original price $109.99Original price$109.99$109.99 - $109.99Current price $109.99 -

For 1996-2004 3.8L 4.6L 5.4L Ford GT SVT GT500 V8 Mustang Cobra EGR Delete kit And Exhaust Cap

SEGULEROriginal price $51.99 - Original price $51.99Original price$51.99$51.99 - $51.99Current price $51.99Placement on Vehicle:Front Billet aluminum IAC (idle air control) and EGR (exhaust gas recirculation) block-off plates add a distinctive touch to ...

View full detailsOriginal price $51.99 - Original price $51.99Original price$51.99$51.99 - $51.99Current price $51.99 -

For 2010-Present Stage 2 ISX 15 CM2250 CM2350 EGR Delete Kit

SEGULEROriginal price $59.99 - Original price $59.99Original price$59.99$59.99 - $59.99Current price $59.99Material: Aluminum Two plates in this kit are made of 6061 aircraft grade billet aluminum anodized and CNC laser cut or CNC machined out of high q...

View full detailsOriginal price $59.99 - Original price $59.99Original price$59.99$59.99 - $59.99Current price $59.99 -

For 2011-2016 6.6L GMC Chevy Duramax Diesel LML EGR Valve Cooler Delete Kit

SEGULEROriginal price $66.49 - Original price $66.49Original price$66.49$66.49 - $66.49Current price $66.49Material: Stainless steel, billet aluminum. Eliminate soot and block of EGR valve prevent high EGT from flow back into engine. Quicker turbo spoo...

View full detailsOriginal price $66.49 - Original price $66.49Original price$66.49$66.49 - $66.49Current price $66.49 -

For 2011-2023 6.7L Ford Powerstroke Diesel EGR Delete Kit

SEGULEROriginal price $85.99 - Original price $85.99Original price$85.99$85.99 - $85.99Current price $85.99Material: Aluminum alloy,Stainless steel. 10mm Hole exhaust cover plate for Ford EGT Probes. CNC machine of billet aluminum and stainless steel m...

View full detailsOriginal price $85.99 - Original price $85.99Original price$85.99$85.99 - $85.99Current price $85.99 -

For 2004-2005 6.6L Chevy GMC Silverado LLY Duramax Diesel EGR Delete Kit

SEGULEROriginal price $92.99 - Original price $92.99Original price$92.99$92.99 - $92.99Current price $92.99Material: Aluminum,Stainless steel,Silicone Eliminates soot build-up and clogged EGR Valves Direct replacement. No installation instruction. No Gl...

View full detailsOriginal price $92.99 - Original price $92.99Original price$92.99$92.99 - $92.99Current price $92.99 -

For 2014-2019 3.0L Dodge Ram 1500 EcoDiesel EGR Valve & Cooler Delete Kit

SEGULEROriginal price $72.99 - Original price $72.99Original price$72.99$72.99 - $72.99Current price $72.99Material: Aluminum,Stainless steel,Silicone. Eliminates soot build-up and clogged EGR Valves. EGR removed and the temperature in the engine compa...

View full detailsOriginal price $72.99 - Original price $72.99Original price$72.99$72.99 - $72.99Current price $72.99 -

For 2006-2007 6.6L Chevrolet Silverado Classic GMC Duramax LBZ Diesel EGR Valve Cooler Delete Kit

SEGULEROriginal price $63.49 - Original price $63.49Original price$63.49$63.49 - $63.49Current price $63.49Material: Aluminum,Stainless steel,Silicone Eliminates soot build-up and clogged EGR Valves Guaranteed to last under high temperatures and pressu...

View full detailsOriginal price $63.49 - Original price $63.49Original price$63.49$63.49 - $63.49Current price $63.49 -

Seguler 2003-2007 6.0L FORD Powerstroke Diesel EGR Cooler Delete Kit

SEGULEROriginal price $56.14 - Original price $56.14Original price$56.14$56.14 - $56.14Current price $56.14Material: 304 stainless steel,Aluminum billet. Eliminate ash accumulation and EGR valve blockage. Improve the cooling effect and reduce the engi...

View full detailsOriginal price $56.14 - Original price $56.14Original price$56.14$56.14 - $56.14Current price $56.14 -

Seguler 2010-2024 6.7L Dodge Ram Cummins Diesel EGR Valve Cooler Delete Kit

SEGULEROriginal price $89.99 - Original price $89.99Original price$89.99$89.99 - $89.99Current price $89.99Material: Aluminum alloy,silicone This kit is intended for off road use. Eliminates soot build up and clogged EGR Valves. Hot exhaust gasses ar...

View full detailsOriginal price $89.99 - Original price $89.99Original price$89.99$89.99 - $89.99Current price $89.99 -

Seguler 2011-2016 6.6L GMC Chevy Duramax Diesel LML Up-Pipe & EGR Valve Cooler Delete Kit

SEGULEROriginal price $173.86 - Original price $173.86Original price$173.86$173.86 - $173.86Current price $173.86Material: 304 Stainless Steel. Reduce the amount of carbon deposited from exhaust to intake. Thanks to its fast airflow and superior engineered ex...

View full detailsOriginal price $173.86 - Original price $173.86Original price$173.86$173.86 - $173.86Current price $173.86 -

Seguler 2003-2007 6.0L Ford F250 F350 Powerstroke Diesel EGR Basic Cooler Kit

SEGULEROriginal price $79.99 - Original price $79.99Original price$79.99$79.99 - $79.99Current price $79.99CNC machine of Aluminum and Stainless Steel billets. Resist corrosion and rust for a long time and has good heat dissipation. Reduce component a...

View full detailsOriginal price $79.99 - Original price $79.99Original price$79.99$79.99 - $79.99Current price $79.99 -

For 1983-1997 Ford F150 F250 F350 Mustang Trucks EGR Delete Block Off Plate Kit

SEGULEROriginal price $22.87 - Original price $22.87Original price$22.87$22.87 - $22.87Current price $22.87Material: Aluminum alloy. Easy installation,and convenient to use. Made of CNC milled from aircraft grade Billet aluminum. Will Not Warp or Deform...

View full detailsOriginal price $22.87 - Original price $22.87Original price$22.87$22.87 - $22.87Current price $22.87 -

Seguler 2017-2019 L5P Duramax Diesel 4pcs L5P Can Bus Plugs Connector Replacement

SEGULEROriginal price $64.99 - Original price $64.99Original price$64.99$64.99 - $64.99Current price $64.99Material: ABS For use with an Aftermarket Exhaust System. A new engine calibration is required. Plugs will replace NOX and DEF modules. The L...

View full detailsOriginal price $64.99 - Original price $64.99Original price$64.99$64.99 - $64.99Current price $64.99 -

For 2011-2023 6.7L Ford F250 F350 F450 F550 Powerstroke Diesel EGR Valve Delete Cooler Delete Kit

SEGULEROriginal price $55.99 - Original price $55.99Original price$55.99$55.99 - $55.99Current price $55.99Material: Aluminum alloy,Stainless steel. Black Anodized components for better durability. 12mm Hole exhaust cover plate for Ford EGT Probes. E...

View full detailsOriginal price $55.99 - Original price $55.99Original price$55.99$55.99 - $55.99Current price $55.99 -

For 2017-2023 6.6L Chevy GMC Duramax L5P diesel EGR Valve Cooler Delete kit

SEGULEROriginal price $131.99 - Original price $131.99Original price$131.99$131.99 - $131.99Current price $131.99Material:Aluminum Alloy ,Stainless steel,Silica gel Improved Performance: Eliminating the EGR system leads to better exhaust flow and faster tur...

View full detailsOriginal price $131.99 - Original price $131.99Original price$131.99$131.99 - $131.99Current price $131.99 -

Seguler 3" Ecodiesel DPF Delete Pipe & EGR Delete kit for 2014-2018 3.0L Ram

SEGULEROriginal price $342.00 - Original price $342.00Original price$342.00$342.00 - $342.00Current price $342.00Material: High quality stainless steel Inlet Diameter: 3.0" Eliminates soot build-up and clogged EGR Valves Specialized designs to ensure a perfec...

View full detailsOriginal price $342.00 - Original price $342.00Original price$342.00$342.00 - $342.00Current price $342.00 -

Seguler 2020-2023 chevy duramax L5P Diesel Can Bus Plugs Connector

SEGULEROriginal price $69.99 - Original price $69.99Original price$69.99$69.99 - $69.99Current price $69.99For use with aftermarket exhaust systems or delete pipes Used when removing the DPF/DEF systems These plugs will go in place of the NOx and DEF mo...

View full detailsOriginal price $69.99 - Original price $69.99Original price$69.99$69.99 - $69.99Current price $69.99 -

For 2007-2010 Cummins ISX CM871 EGR Plug Kit Stage 2 Plates and Plugs Aluminum

SEGULEROriginal price $67.99 - Original price $67.99Original price$67.99$67.99 - $67.99Current price $67.99Material:304 Stainless Steel & Billet Aluminum. High-temperature graphite gaskets are adopted to prevent leakage. Used to delete the EGR val...

View full detailsOriginal price $67.99 - Original price $67.99Original price$67.99$67.99 - $67.99Current price $67.99 -

For 11-23 Ford 6.7L Powerstroke CCV/PCV Reroute/Delete Engine Ventilation Kit

SEGULEROriginal price $72.00 - Original price $72.00Original price$72.00$72.00 - $72.00Current price $72.00Material:Aluminum alloy rubber. Black Anodized components for better durability. This Crankcase Ventilation System provides a SOLID solution to ...

View full detailsOriginal price $72.00 - Original price $72.00Original price$72.00$72.00 - $72.00Current price $72.00 -

For 2013-2023 6.7L Dodge Ram Cummins Cab & Chassis EGR Delete Kit Diesel

SEGULEROriginal price $62.99 - Original price $62.99Original price$62.99$62.99 - $62.99Current price $62.99Material: Aluminum alloy. Eliminates soot build up and clogged EGR Valves. Hot exhaust gasses are not being re-routed back into the motor. Coo...

View full detailsOriginal price $62.99 - Original price $62.99Original price$62.99$62.99 - $62.99Current price $62.99 -

For 2013-2018 6.7L Dodge RAM 2500 3500 Cummins Diesel EGR Delete Cooler Throttle Valve Delete Kit

SEGULEROriginal price $112.00 - Original price $112.00Original price$112.00$112.00 - $112.00Current price $112.00Material: Aluminum alloy,silicone Aluminum material can resist corrosion and rust for a long time and has good heat dissipation. EGR delete stan...

View full detailsOriginal price $112.00 - Original price $112.00Original price$112.00$112.00 - $112.00Current price $112.00 -

For 1986-1995 2.8L 4.9L 5.0L 5.8L 7.5L Ford F150 F250 Bronco EGR Simulator Eliminator Delete/EGR Delete

SEGULEROriginal price $59.99 - Original price $59.99Original price$59.99$59.99 - $59.99Current price $59.99isconnect your stock EGR valve and breathe life into your motor, while keeping your check engine light off, but active for future problems! This...

View full detailsOriginal price $59.99 - Original price $59.99Original price$59.99$59.99 - $59.99Current price $59.99

Leave a comment